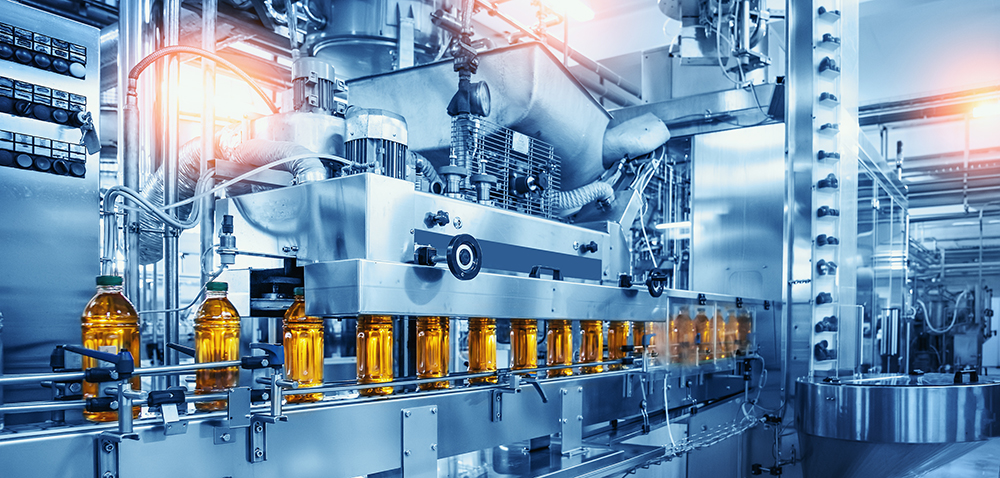

How Durlon® Sealing Solutions Revolutionized Food Processing

In the competitive world of food processing, maintaining high standards of product quality is crucial. One of North America’s largest chocolate suppliers faced a challenge that many in the industry can relate to: finding a reliable sealing solution for their equipment. This case study highlights how Durlon® 9000 PTFE gaskets and Durlon® Joint Sealant provided […]