Sulfuric acid, a cornerstone of industrial processes, is widely utilized across sectors such as chemical manufacturing, transportation, and processing. Its highly corrosive nature demands precision in selecting gasket materials to ensure the safety of equipment, personnel, and the environment. A mismatch in gasket compatibility can lead to costly equipment failures, leaks, or Non-Accidental Releases (NARs), which carry severe risks.

The Importance of Chemical Resistance in Gaskets

The aggressive nature of sulfuric acid necessitates gaskets with superior chemical resistance. This is especially crucial in high-stakes industries such as rail transport, where gasket failures can have significant safety and environmental repercussions. Gasket Resources Inc. (GRI), a member of The Sulfur Institute (TSI), specializes in providing gasket solutions tailored to mitigate these risks.

Challenges in Sulfuric Acid Applications

Sulfuric acid presents unique challenges based on its concentration and temperature. GRI’s expertise as the only custom gasket manufacturer associated with The Sulfur Institute equips us to address these challenges effectively. To simplify material selection, sulfuric acid is categorized into three key sub-groups:

- Sulfuric Acid (20% Concentration):

Requires materials resistant to dilute acidic environments. - Sulfuric Acid Concentrate (70%–98%):

Demands enhanced chemical resistance due to higher concentrations. - Sulfuric Acid Concentrate (>200°F):

Combines extreme temperature and chemical compatibility requirements.

Recommended Gasket Materials

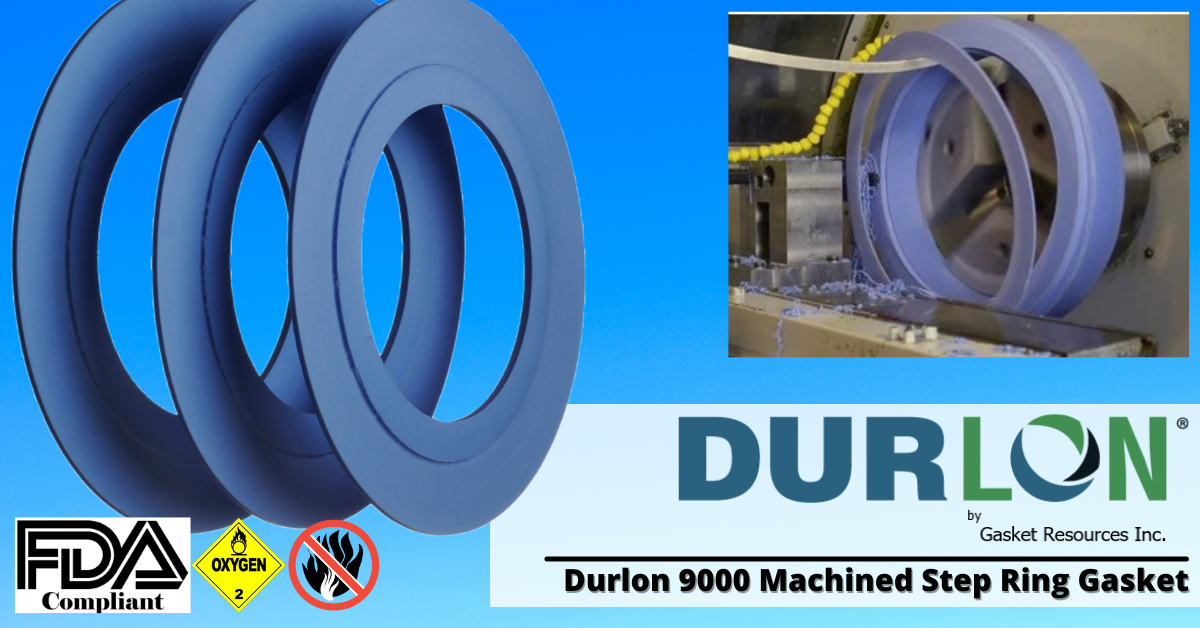

Durlon® 9000 Step Ring Gasket

The Durlon 9000 Step Ring Gasket is the gold standard for sulfuric acid applications, excelling across all concentrations. Its design integrates PTFE resins with inorganic fillers, eliminating wicking while resisting sulfuric acid’s corrosive effects. With high dielectric strength and superior sealability, this gasket is particularly effective when paired with Mondi® piping systems, offering durability and leak prevention even under demanding conditions.

Identa-Seal Viton B Blue

For applications requiring elastomer gaskets, Identa-Seal Viton B Blue delivers exceptional performance. It is the only Genuine Viton® gasket meeting DuPont SU2A specifications, providing superior resistance to chemical degradation and high temperatures. This material is ideal for applications where flexibility, resilience, and compatibility are crucial.

Best Practices for Safe Sulfuric Acid Handling

- Proper Venting

Before loading or unloading sulfuric acid, ensure tank cars are vented to prevent pressure buildup. Operators must adhere to site-specific procedures and wear appropriate personal protective equipment (PPE) to avoid exposure to hazardous acid mists or splashes.

- Gasket Inspection and Maintenance

Regular inspection of gaskets, including rupture disc and sealing gaskets, is essential. Replace gaskets exhibiting wear, defects, or damage to maintain a secure seal and prevent leaks.

- Thorough Rinsing

After loading or unloading, rinse all contact surfaces with fresh water to remove residual acid. This practice prolongs equipment life and minimizes the risk of accidental acid exposure during subsequent operations.

Optimize Your Gasket Selection with GRI

Selecting the right gasket material for sulfuric acid applications is essential to ensure operational safety and efficiency. GRI’s Chemical Compatibility Tool offers a user-friendly platform to evaluate compatibility and find the optimal gasket for your specific needs.

Whether you’re handling low concentrations, concentrated acids, or elevated temperatures, GRI’s range of high-performance gaskets ensures safety and reliability. Contact our team today for expert advice and customized solutions tailored to your application.

By choosing the appropriate gasket materials, such as Durlon® 9000 or Identa-Seal Viton B Blue, and adhering to industry-leading practices, businesses can mitigate risks and enhance the safety of sulfuric acid handling. For comprehensive guidance and access to advanced gasket technologies, trust GRI as your partner in safety and performance.